Incom is the world’s leader in polymer and glass microstructure innovation. Our newest revolutionary technologies range from the highest resolving imaging optic ever made to the world’s largest and fastest MCP based photodetector.

Incom’s customers are researchers and instrument makers at the forefront of technology. We are pleased to aid our innovative contributions to science, medicine, security, and display technology. Providing solutions to critical applications has enabled our customers to develop next generation technologies that have shaped the world around us.

Products

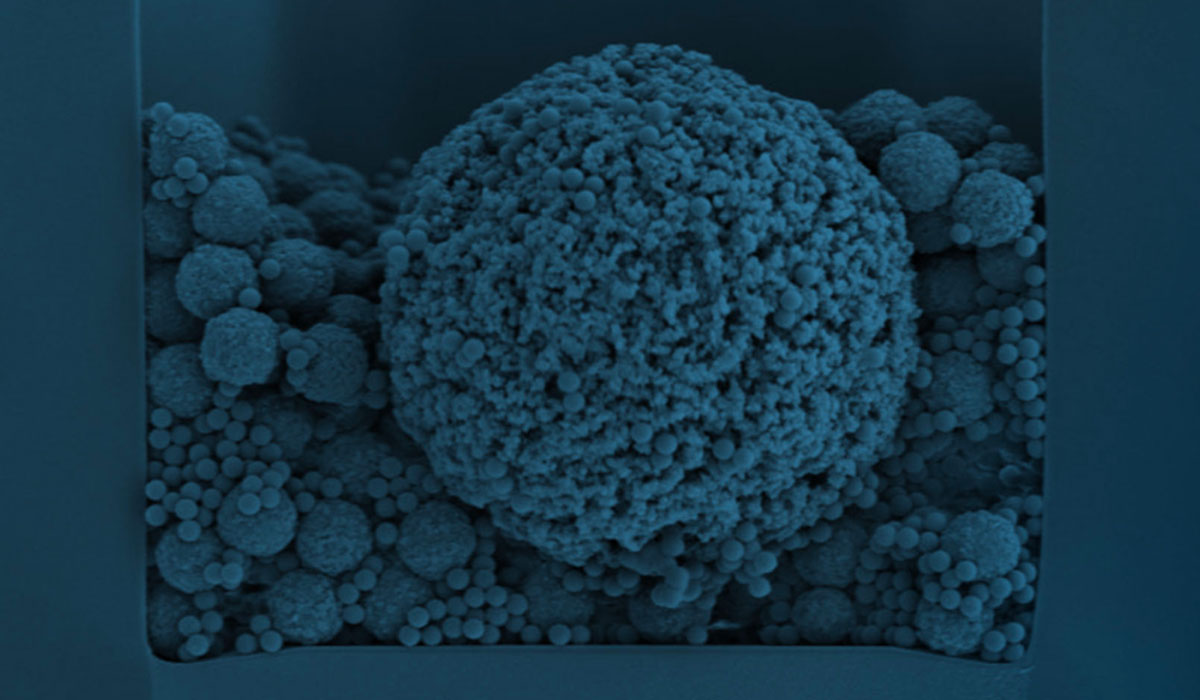

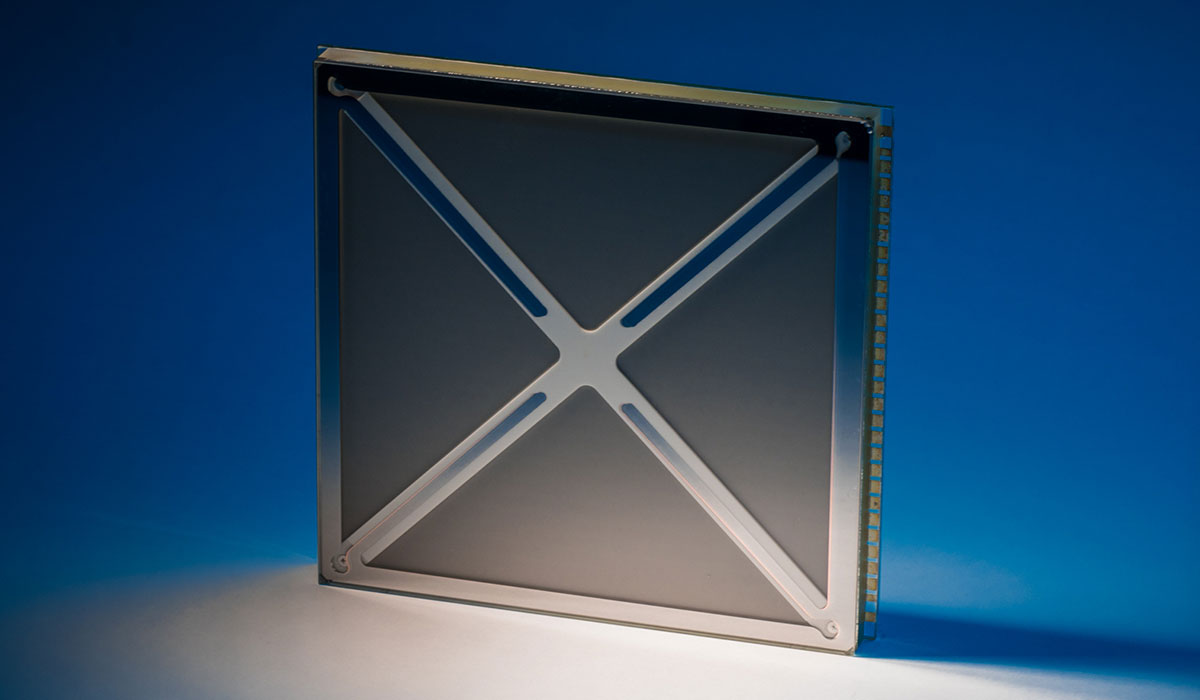

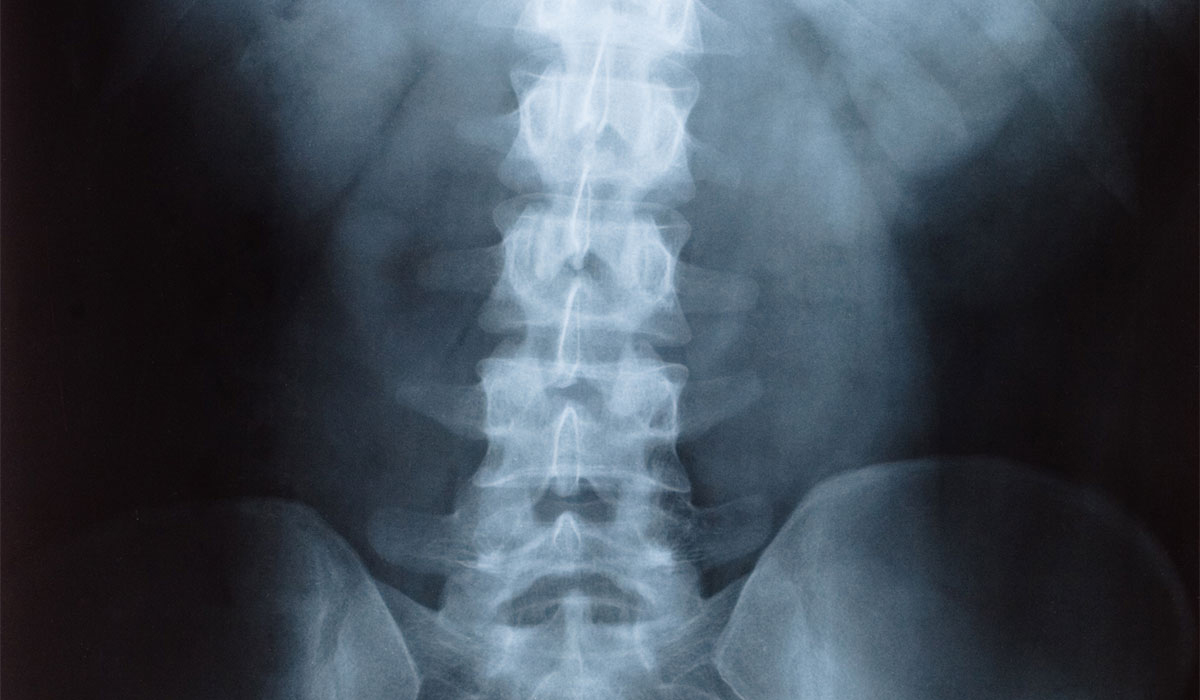

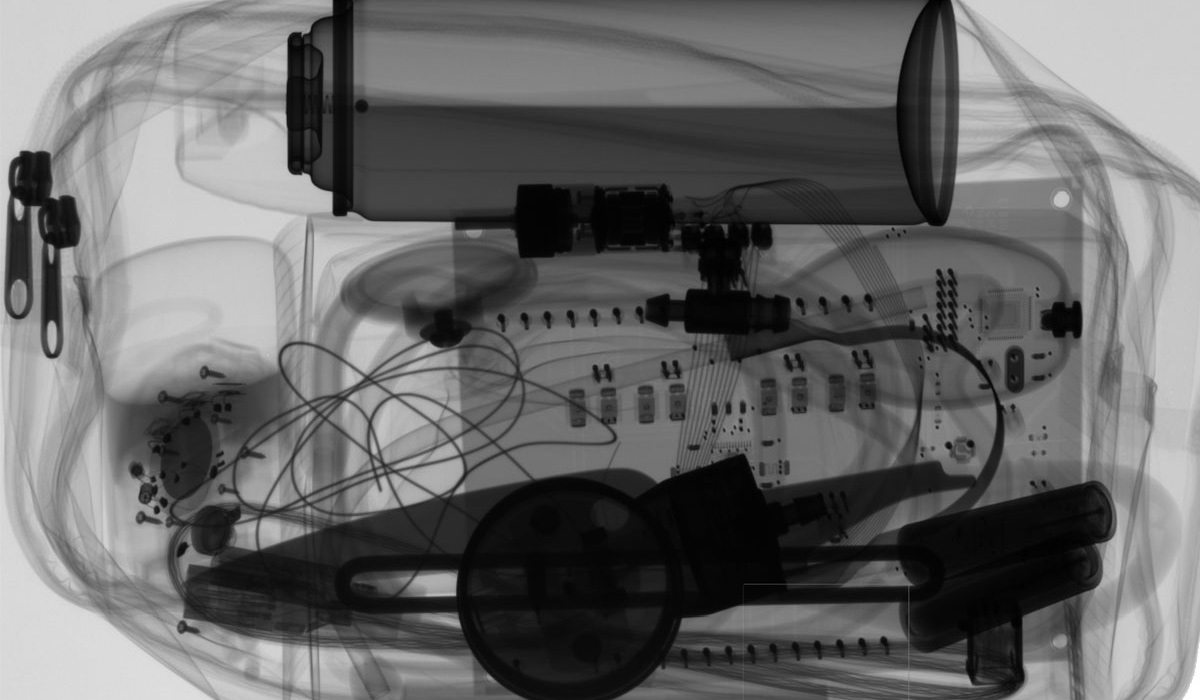

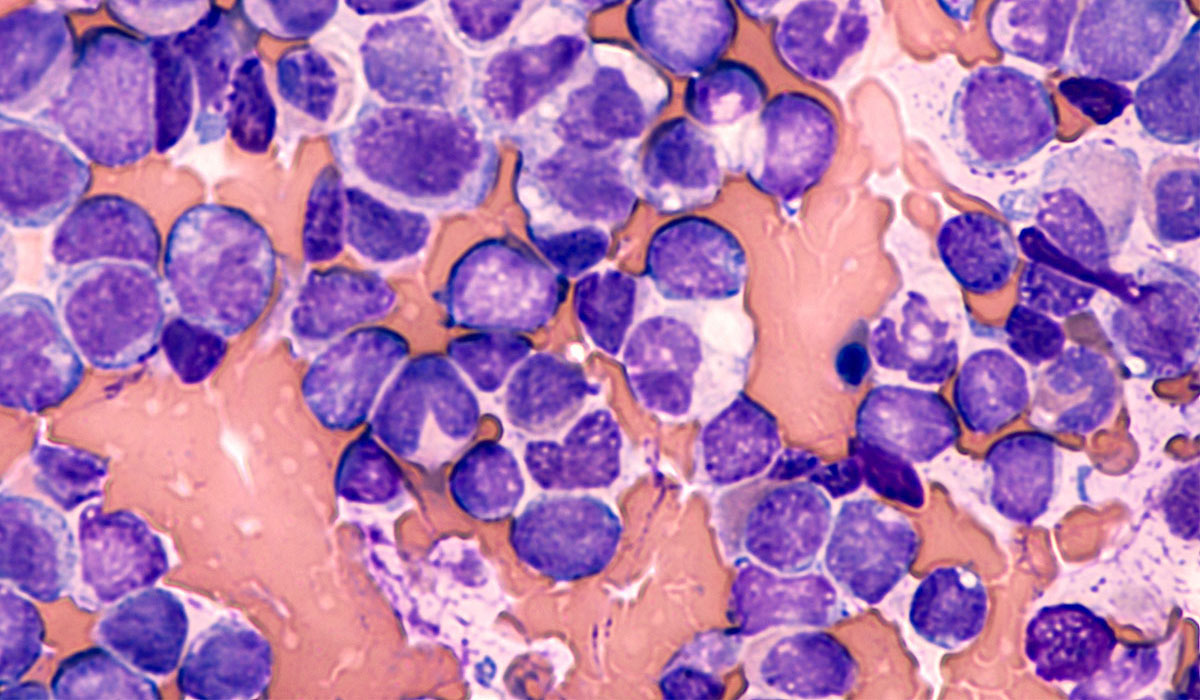

As the world’s leading innovator in glass and polymer microstructures, Incom has worked with OEM manufacturers in numerous technological fields, from high energy physics to medical and dental equipment. As our technology continues to advance, its usefulness spreads to even more aspects of our daily lives: Homeland security uses Incom MCPs and LAPPDs to detect nuclear threats; new drugs are developed more quickly with large area taper arrays used in X-Ray Crystallography; digital mammography, full chest X-rays, and whole body scans are now more accurate than ever because of large area X-Ray attenuating fiber optic faceplates; and VR/AR benefit from Incom’s revolutionary high resolution Nanoguide.

Solutions for Industries

Incom serves a growing number of markets with polymer and glass microstructures and comprehensive resources for co-development, customizing, and prototyping. Our partnership with OEMs allow us to make critical contributions to genetic, medical, dental, drug research, scientific, defense, homeland security, and display technology applications. Our components have been essential to the innovative technology emerging in these fields. Explore our site to learn more about the markets we serve and see why Incom is enabling the vision of tomorrow.

Trade Shows

PITTCON

Boston, MA

SPIE Photonics West

San Francisco, CA